Wood-Free Paper: Composition, Manufacturing, Properties, and Applications

Wood-free paper is a widely used category of paper that, despite its name, is not made without wood. Instead, the term refers to paper produced without mechanical wood pulp, relying primarily on chemical pulp from which lignin has been removed. This distinction is crucial because lignin is responsible for yellowing, brittleness, and reduced longevity in paper. As a result, wood-free paper is valued for its durability, print quality, and suitability for archival and professional applications.

Raw Materials and Fiber Sources

Wood-free paper is typically manufactured from hardwoods (such as eucalyptus or birch) and softwoods (such as pine or spruce). These woods are selected for their cellulose fiber characteristics:

- Cellulose fibers provide strength and flexibility.

- Hemicellulose contributes to bonding between fibers.

- Lignin, which is largely removed, would otherwise cause discoloration and degradation.

In some cases, non-wood fibers such as cotton, bamboo, or bagasse may be blended in to enhance specific properties, but traditional wood-free paper is predominantly cellulose-based.

Pulping Process

The defining technical feature of wood-free paper lies in its pulping method.

Chemical Pulping

Chemical pulping processes—most commonly the kraft (sulfate) process or the sulfite process—are used to separate cellulose fibers from lignin:

- Kraft process: Uses sodium hydroxide and sodium sulfide to dissolve lignin, producing strong fibers with high tear resistance.

- Sulfite process: Uses sulfurous acid and bisulfite ions, yielding brighter pulp but generally weaker fibers.

These processes remove up to 90–95% of lignin, resulting in a pulp that is chemically stable and resistant to aging.

Bleaching and Brightness Control

After pulping, the fibers undergo bleaching to improve brightness and color consistency. Modern wood-free paper production emphasizes elemental chlorine-free (ECF) or totally chlorine-free (TCF) bleaching to reduce environmental impact.

Brightness is measured on standardized scales (such as ISO brightness), and different grades of wood-free paper are produced depending on the intended application—from high-brightness paper for color printing to more natural shades for books and stationery.

Fillers and Additives

To enhance performance, manufacturers incorporate fillers and chemical additives, including:

- Calcium carbonate or kaolin clay for opacity and smoothness

- Sizing agents (alkyl ketene dimer or rosin) to control ink absorption

- Optical brightening agents (OBAs) to increase perceived whiteness

- Retention aids and strength additives to improve sheet formation

The careful balance of these components determines printability, stiffness, surface texture, and runnability on printing presses.

Physical and Mechanical Properties

Wood-free paper is known for several key technical properties:

- High aging resistance due to low lignin content

- Dimensional stability, minimizing curling and expansion

- Smooth surface, especially in coated wood-free grades

- Good ink holdout, allowing sharp text and vivid images

- High tensile and tear strength, particularly in uncoated grades

These properties make it suitable for both high-speed digital printing and traditional offset lithography.

Coated vs. Uncoated Wood-Free Paper

Wood-free paper is available in both coated and uncoated forms:

- Uncoated wood-free paper is commonly used for books, office paper, legal documents, and notebooks due to its readability and writability.

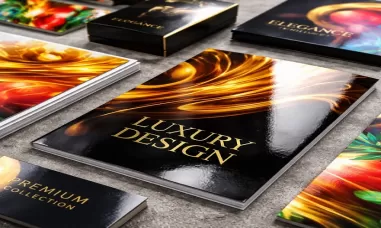

- Coated wood-free paper includes a mineral coating layer that improves gloss, color reproduction, and image sharpness, making it ideal for magazines, brochures, and marketing materials.

Environmental Considerations

Although wood-free paper offers superior quality, its environmental footprint depends heavily on sourcing and processing practices. Sustainable production involves:

- Certified forestry (FSC or PEFC)

- Energy-efficient pulping processes

- Closed-loop chemical recovery systems

- Reduced water consumption and emissions

When responsibly produced, wood-free paper can be both high-performance and environmentally responsible.

Applications

Wood-free paper is used across a wide range of industries:

- Publishing: textbooks, novels, academic journals

- Corporate and legal sectors: reports, contracts, letterheads

- Education: notebooks, examination papers

- Commercial printing: catalogs, flyers, annual reports

- Archival use: documents requiring long-term preservation

Its reliability and consistency make it a standard choice where quality and longevity are critical.

Wood-free paper represents a technically advanced class of paper products designed for durability, print excellence, and professional use. By eliminating mechanical pulp and minimizing lignin content, manufacturers achieve superior aging characteristics and performance. Understanding its composition, production processes, and properties highlights why wood-free paper remains a cornerstone material in publishing, printing, and documentation despite increasing digitalization.